VISUAL COMPONENTS ROBOTICS OLP

Discover how you can save time, reduce costs, and improve production performance with Offline Robot Programming (OLP) Software.

Visual Components Robotics OLP (previously Delfoi ARC 4) is fast and user-friendly remote programming software for main robot brands. Software utilizes CAD-models and integrated WPS (Welding parameter database) for high-quality welds.

One Software For All Processes

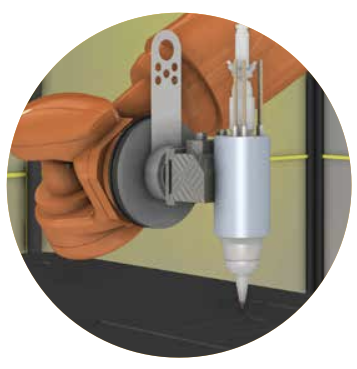

With Visual Components Robotics OLP (Offline Robot Programming) software you can program robots to do precise welds, buffs, grinds, cuts or paints.

The software is the result of more than 20 years of intensive development work together with our customers to fulfill even their most demanding needs. The trail blazing Visual Components Robotics OLP software for offline programming of arc welding robots has won all benchmarks when measuring programming speed and ease of use since its release in 2012.

- FAST AND USER-FRIENDLY SOFTWARE

Visual Components Robotics OLP is very fast and user-friendly offline programming software for all major robot brands. - HIGH QUALITY PROGRAMS

Integrated databases to manage custom WPS (Welding Procedure Specification) ensure high quality welds. - ACCURATE PATHS

Advanced calibration tools and using a welding robot as measuring device:

– no need for external calibration devices. - COMPATIBLE WITH MAIN ROBOT BRANDS

Program your robots regardless of brand or type. Software supports 17 of the most common robot brands. - UP TO 10x FASTER PROGRAMMING

Generate programs fast in virtual robot cells and let the software validate and optimize programs before sending anything to production to avoid costly errors. - UTILIZES CAD MODELS

The software effectively utilizes the features of CAD models.

* Welding Procedure Specification

Visual Components Robotics OLP's properties

- Offline Robot Programming (OLP)

- Automatic and instant creation of welds

– even for complex curved and double curved welds - Automatic creation of welds over sharp corners

- Very easy and fast editing and manipulation of a robot arm for the best welding position

- Errorless robot translators also with true uploading functionality

- Improved visualization capabilities – showing weld dimensions

- Realistic simulation of welding cables

- Seam search management (1D, 2D, 3D)

- Multi-pass welding management and automatic generation of passes

- Stich welding

- Copying, chaining, grouping and mirroring (for mirror symmetric work pieces) of welds

- Management of welding process settings and features

- Welding parameter database for WPS

- Automated calculation of external robot axes

- Versatile calibration tools by using a welding robot as a measuring device to ensure extreme precision in the programming of modelled cells

Read more about automation and Visual Components OLP -software

- MAJA Engineering YouTube - channel

- Visual Components - forum

- Visual Components - brochure (PDF)

- Visual Components – website